Automatic Top-in IML System

Automatic Top-in IML System

Automatic Top-in IML System automates the in-mold labeling process for large products, using a dedicated robot to place labels with precision, ensuring high-quality, seamless integration

Share:

Automatic Top-in IML System

Features:

- Our Automatic Top-in IML System is designed for large products with long cycle times.

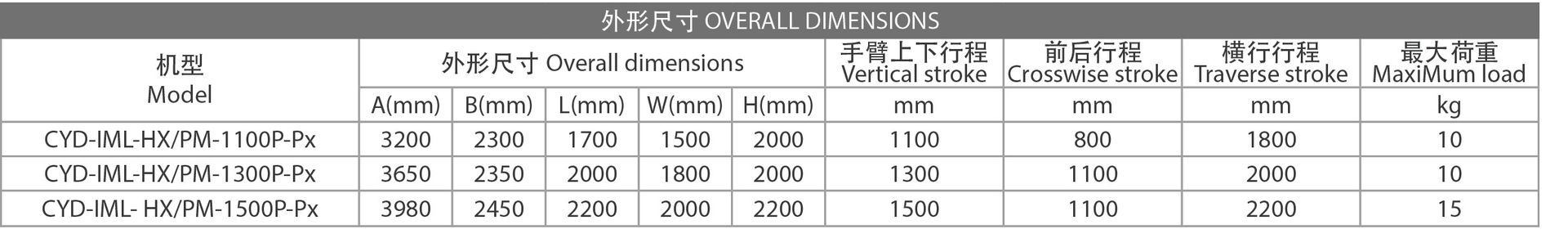

- The system consists of a dedicated Top-In labeling robot, a label magazine, a stacking robot, and a conveyor system.

- The Top-In robot and label magazine are separate units. The labeling robot is mounted directly on the injection molding machine, which ensures high labeling accuracy and minimizes vibration.

- The Top-In robot is a versatile component that can also be used for part removal once the IML production run is complete.

- Our Automatic Top-in IML System is highly flexible; it can be adapted for different bucket sizes by simply changing the label magazine and jig. This design reduces future investment for expanded production.

- The inclusion of a stacking robot and conveyor enables a fully automated production line.

- Our Automatic Top-in IML System is engineered to meet European food-grade standards and is CE-certified.